Introduction

Construction sites are rife with diverse airborne hazards, ranging from dust and fumes to chemicals and biological contaminants. These hazards pose significant risks to the health and safety of construction workers. Respirators are an indispensable line of defense, mitigating the dangers posed by these airborne particles.

Airborne Hazards in Construction

- Particulate Matter: Dust, sawdust, and concrete particles are ordinary in construction settings. Prolonged exposure can lead to respiratory issues like bronchitis and silicosis.

- Chemical Fumes: Adhesives, paints, solvents, and cleaning agents release harmful fumes that can cause respiratory irritation and long-term health issues.

- Biological Contaminants: Mold, bacteria, and other biological agents thrive in moist environments, such as those often found during construction. Inhalation of these contaminants can lead to allergies and respiratory infections.

Role of Respirators

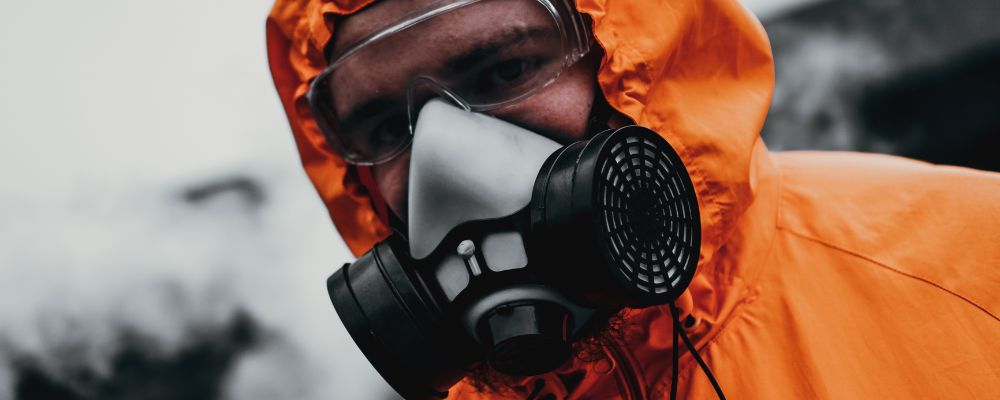

Respirators act as protective gear designed to filter out harmful particles and contaminants from the air, safeguarding the respiratory system of construction workers. They come in various types and configurations, each suited for specific hazards and environments.

-

Significance for Worker Safety

The importance of respirators in construction cannot be overstated. They significantly reduce the risk of inhalation-related health problems, ensuring that workers can perform their duties in a safer environment. Moreover, by protecting the respiratory system, they contribute to overall worker well-being, enabling sustained productivity and minimizing absences due to respiratory illnesses.

-

Compliance with Safety Regulations

Regulatory bodies like OSHA (Occupational Safety and Health Administration) have stringent guidelines mandating respirators in hazardous work environments. Compliance with these regulations is not just a legal requirement but a crucial step in preserving the health and safety of construction workers.

In conclusion, respirators are not just accessories but lifelines in the construction industry. Their role in protecting against many airborne hazards is pivotal, ensuring the well-being of workers and compliance with safety standards.

Types of Respirators

CH RESPIRATOR KN95 WHITE

The CH Respirator KN95 White is engineered to provide high-level protection against particulate matter, making it a crucial safety gear for construction workers exposed to airborne hazards. Its designation as KN95 signifies compliance with Chinese standards, ensuring a filtration efficiency of at least 95% against non-oil-based particles.

Key Features:

- Filtration Efficiency: Meeting stringent standards, it efficiently filters out harmful particles, including dust, pollen, and other airborne contaminants commonly found on construction sites.

- Comfort and Fit: The respirator is designed to offer a snug yet comfortable fit, minimizing gaps that might compromise its protective efficacy.

- Multi-Layered Protection: Utilizing multiple layers of specialized materials, it provides a barrier against various sizes of particulates.

Usage Recommendation:

- Suitable for environments where protection against particulate matter is essential, such as sanding, drilling, or cutting tasks in construction.

North P100 Safety Particulate Filter 7580P100 – 1 Pair

The North P100 Safety Particulate Filter 7580P100 is a reliable filter pair that ensures top-notch protection against particulates. It is constructed with precision and meets rigorous safety standards, making it an ideal accessory for construction workers operating in hazardous environments.

Key Features:

- High-Level Protection: Specifically designed to offer a high level of protection against a broad spectrum of particulates, including hazardous dust, fumes, and mists.

- Durable Construction: The filters are built to withstand harsh conditions, ensuring durability and longevity in challenging work settings.

- Compatibility: Designed to integrate with compatible respirators, enhancing their filtration capabilities seamlessly.

Usage Recommendation:

- It is ideal for construction tasks involving exposure to heavy dust, toxic fumes, and other harmful particles.

Honeywell 7700 Series Half Mask Respirator 770030

The Honeywell 7700 Series Half Mask Respirator stands out for its comfort and reliability, making it a valuable asset for construction workers. Engineered with a focus on durability, it offers a protective solution in hazardous work environments.

Key Features:

- Comfortable Design: Ergonomically designed to ensure wearer comfort without compromising safety, allowing for extended usage without discomfort.

- Reliable Protection: Provides a reliable barrier against airborne hazards while allowing easy breathing and minimal resistance.

- Durability: Constructed from high-quality materials, the respirator is built to withstand rugged conditions, ensuring longevity and consistent performance.

Usage Recommendation:

- It is suited for various construction tasks where a balance between comfort, reliability, and protection is crucial.

Honeywell North 7600 Series Niosh Approved Full Face Respirator Dual Cartridge Silicone 760008A

The Honeywell North 7600 Series Niosh Approved Full Face Respirator is a comprehensive protective solution equipped with a dual-cartridge system and Niosh approval, offering high protection for construction workers exposed to diverse hazards.

Key Features:

- Full-Face Coverage: Provides comprehensive protection for the face, eyes, and respiratory system, safeguarding against various airborne contaminants.

- Dual Cartridge System: Enhances filtration efficiency by utilizing double cartridges, offering protection against particulates.

- Niosh Approval: Meets Niosh standards, ensuring conformity with stringent safety regulations.

Usage Recommendation:

- Suitable for scenarios demanding full-face protection, such as tasks involving exposure to gases, vapors, and fine particulates in construction environments.

Each of these respirators serves as a specialized safety solution catering to specific needs and hazards encountered by construction workers, ensuring their safety and well-being in hazardous work environments.

Choosing the Right Respirator

Construction workers encounter diverse hazards, and choosing the fitting respirator is critical for adequate protection. Several factors should be considered:

- Job-Specific Hazards Identification: Assess the specific risks on the construction site. Is it dust, chemical fumes, gases, or biological contaminants? Each hazard demands a different respirator type.

- Filtration Efficiency: Different respirators offer varying levels of protection. Understanding the Minimum Efficiency Reporting Value (MERV) or Assigned Protection Factor (APF) helps select the appropriate respirator for the hazard intensity.

- Fit and Seal: A proper fit is paramount for a respirator’s effectiveness. Workers must undergo fit testing to ensure a secure seal around the face, preventing contaminated air from seeping in.

- Comfort and Wearability: Construction work involves long hours. Comfortable respirators encourage consistent usage. Consider factors like weight, straps, and overall comfort during prolonged wear.

Proper Usage and Maintenance

Even the best respirator requires proper handling and care to maintain its effectiveness:

- Fitting Instructions: Train workers on appropriate procedures to ensure a tight seal. Incorrectly worn respirators compromise safety.

- Regular Inspection: Routinely inspect respirators for wear, tear, or damage. Damaged parts may compromise filtration efficiency or seal integrity.

- Cleaning Procedures: Provide clear guidelines for cleaning respirators. Mild soap and water are usually recommended. Ensure thorough drying before reuse.

- Storage Practices: Proper storage prevents damage and contamination. Keep respirators in a clean, dry area away from direct sunlight, extreme temperatures, or chemicals.

- Regular Maintenance Schedule: Implement a maintenance schedule for respirators, including regular checks, replacements of filters or cartridges, and periodic fit tests.

- Education and Training: Regular training sessions for workers on proper usage, maintenance, and the importance of adhering to guidelines ensure optimal performance and worker safety.

Adherence to these guidelines guarantees not only the longevity of the respirator but also maintains its effectiveness in protecting workers against hazardous particles, fumes, or contaminants commonly found in construction environments.

Regulatory Standards and Compliance

-

Occupational Safety and Health Administration (OSHA)

Construction workers must adhere to standards set by OSHA, which outline respirator guidelines and regulations. OSHA emphasizes the importance of selecting appropriate respirators based on the hazards present in the construction environment. These standards cover fit testing, proper usage, maintenance, and training programs.

-

National Institute for Occupational Safety and Health (NIOSH)

NIOSH certifies and approves respirators to meet specific safety and filtration standards. Construction workers should prioritize using NIOSH-approved respirators, ensuring the devices offer adequate protection against airborne particles and other hazardous substances commonly found in construction settings.

-

Adherence to Safety Norms

Adhering to regulatory standards set by organizations like OSHA and NIOSH is not just a recommendation but a legal obligation for construction workers. Compliance ensures that respirators used on construction sites effectively mitigate risks associated with airborne contaminants. It also safeguards workers from potential health hazards and provides a safer work environment.

Workers and employers must understand and implement these standards, including conducting fit tests, providing adequate training on proper usage and maintenance, and regularly checking for compliance to ensure the respirators’ effectiveness.

For more information, visit our Facebook page.

For more products, visit our website.

North P100 Safety Particulate Filter 7580P100 – 1 Pair

Honeywell 7700 Series Half Mask Respirator 770030

Honeywell North 7600 Series Niosh Approved Full Face Respirator Dual Cartridge Silicone 760008A

Conclusion

Respirators serve as indispensable protective equipment in the construction industry. They act as a vital barrier against hazardous airborne particles, dust, fumes, and other substances that pose health risks to workers.

Selecting the correct type of respirator tailored to the specific hazards present in the construction environment is equally important. Ensuring proper usage, fitting, maintenance, and adherence to regulatory standards laid out by organizations like OSHA and NIOSH is similarly essential.

In conclusion, the significance of respirators in safeguarding construction workers cannot be overstated. Prioritizing safety by selecting the appropriate respirators and complying with safety standards is paramount to ensure the well-being and health of those working in this challenging and potentially risky environment.